How Energy Management System helps

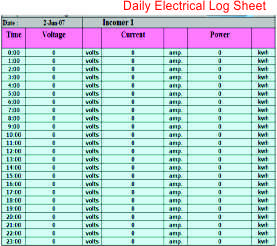

Gives information about Section wise or Department wise Electrical

data and energy consumption for taking corrective actions

Gives a clear picture about energy costs involved into Production/office

Helps to optimize and Monitor Electrical Parameters to achieve Cost

Reduction

Helps future Planning based on consumption patterns

Key Features Communication

Supports Free Configuration for any Modbus Compliant Energy Meter

Parallel processing of devices on multiple COM ports

High Speed archival of data from a large number of devices

Remote Access of Data possible using Client / Server Configuration

Supports Virtual Device concept.

Hence data source of electrical parameters can be SCADA / PLC.

Data access in this case is using OPC Data.

Online Electrical Data Exporting to SCADA using OPC

Hence integration SCADA / PLC systems is possible

Display in Tabular Formats and as Trends

Sub Billing

Sub Billing reports for different areas of plants

Graphical Display of

Maximum Power Demand Analysis

Automatic

Integration of Production and Equipment Run Hours

using OPC

Support for differentiation of Electricity Board and DG power Consumption

Knowing values like consumption, Power factor, Peak demands enables us to take necessary actions and correction at right time